What should you know about Diced silicon wafer with a dry oxide coating?

- Kelly Clifford

- Jan 11, 2021

- 2 min read

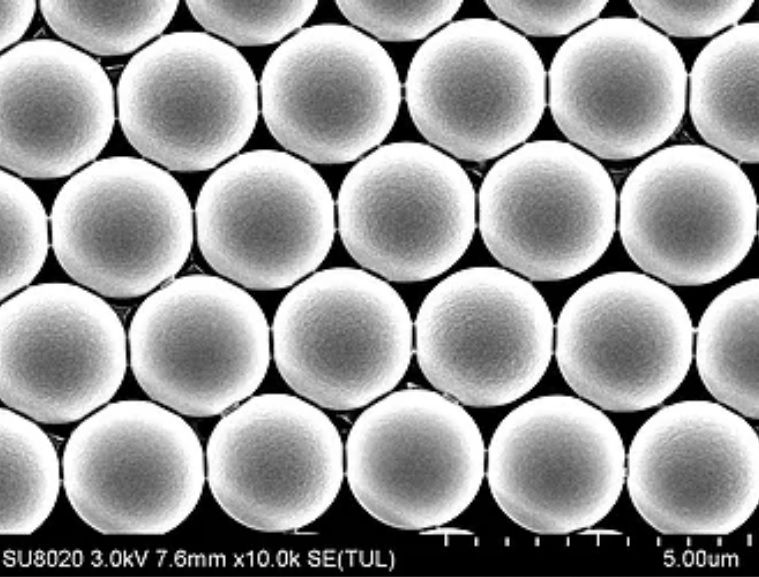

Diced silicon wafer with a dry oxide coating has been used luxuriously in microelectronics and MEMS as a phase for produce. An entrancing assortment of the standard Diced silicon wafer with a dry oxide covering is the SOI substrate. To convey these wafers, two silicon wafers are strengthened together, using silicon dioxide of around 1–2 μm thickness as a bond layer. One of the silicon wafers is debilitated to a thickness of 10–50 μm. The particular layer thickness will depend upon the application. Wafer lessening is performed by wet drawing, so this plan procedure is regularly called the holding and-etchback strategy. The covered oxide layer (BOX) isn't accessible aside from if mass micromachining is performed, either on the decreased top or full-thickness silicon wafer, which similarly goes probably as dealing with a stage for planning. Of course, a remarkable breaking procedure including hydrogen implantation, holding, and warming of the wafer stack to 470°C can be used to make a slim silicon wafer on top of the BOX layer. Holding of a 300 μm quartz wafer sandwiched between two standard 525 μm thick silicon wafers was in like manner outlined.

These strength substrates find applications in force contraptions; electronic assignments for application at raised temperatures, mass micromachined xyz-stages, radio repeat (RF-MEMS) switches, microheater devices for microfluidic applications, and facilitated optical structures.

P-type Boron-doped 200nm SiO2 thermal oxide wafer was submitted to high-temperature annealings during long events in oxygen and in nitrogen climate in order to reproduce comparative meds which are imperative to make power and high voltage semiconductors or diodes. It is showed up by electrical strategies (microwave recognized photoconductivity decay and surface photovoltage) and by exposure techniques (checking infrared amplifying focal point, X-pillar geography, Fourier changed infrared spectroscopy, compound etchings) that annealings in nitrogen added to annealings in oxygen harmfully influence the lifetime of minority carriers and can make separations and quickens.

Comments